Robotic container rotation and warehouse operations for Yazaki using KUKA AMR and a unified RMS platform

Client

Yazaki is an international automotive components manufacturer.

Goal

Reduce costs and speed up warehouse operations by cutting production line downtime through automated container rotation and optimized container logistics.

Challenge

Container rotation was performed manually by low-skilled warehouse staff. This led to: - high payroll costs; - delays in bringing empty containers and removing full ones; - production line downtime of 15 to 30 minutes; - lack of transparency in managing the container fleet.

Solution

To eliminate container-rotation delays and improve production flow efficiency, a comprehensive solution was designed and implemented combining robotics, a proprietary RMS system, and operator mobile interfaces.

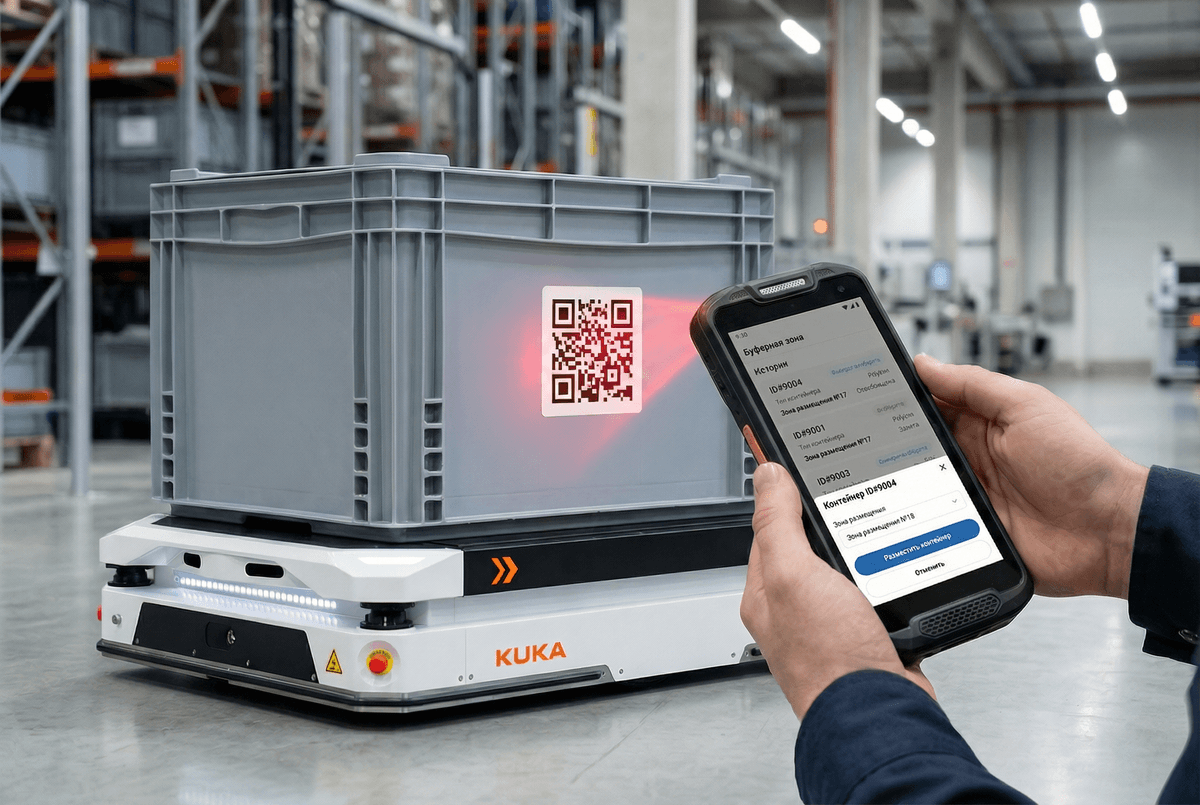

KUKA KMP 1500 autonomous robots

- Supply and commissioning of 4 KUKA KMP 1500 autonomous mobile robots.

- Robots automatically drive under the container stand, lift it, and deliver it to a specified location.

- Integration with the RMS distributes tasks in real time and builds optimal routes.

- Full automation of deliveries, pickups, and container rotation.

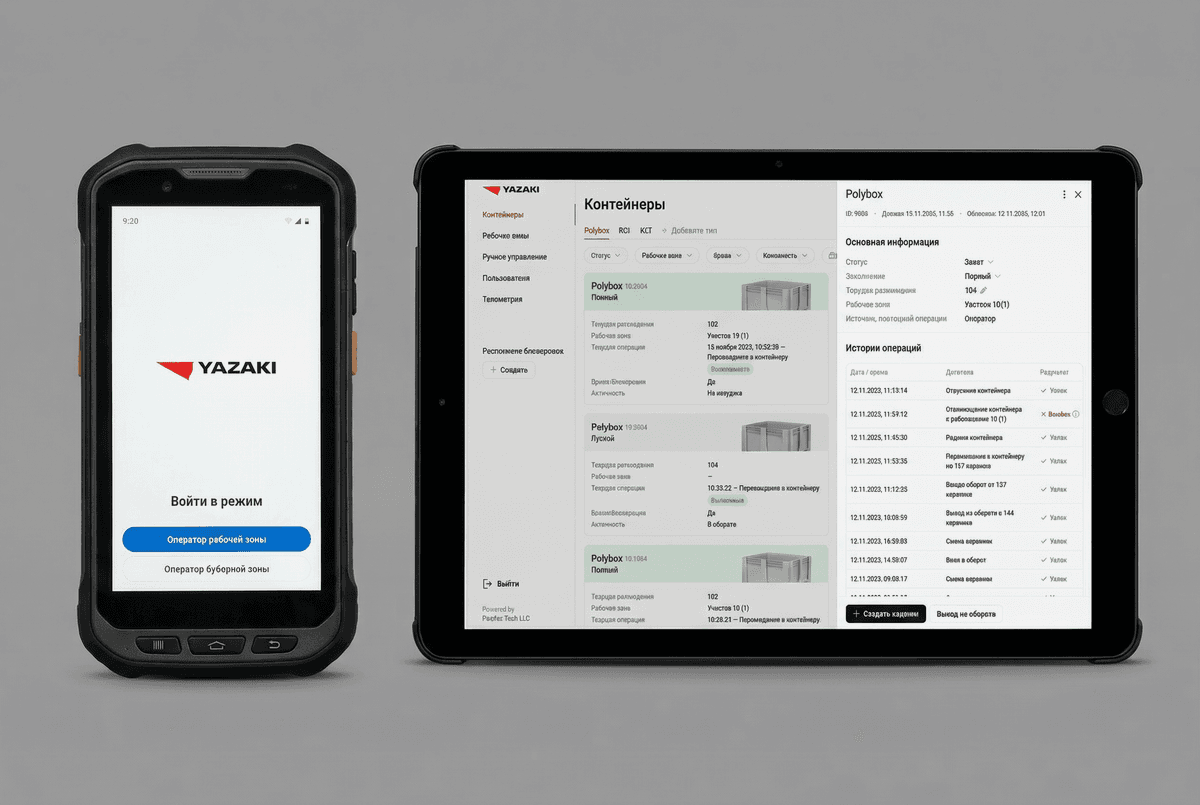

Proprietary RMS platform

- A centralized solution was developed and deployed to manage container states: fill level, activity, in/out-of-circulation status.

- The system tracks container location across production and warehouse areas and manages automatic rotations and replenishment based on priorities.

- Task queue management and distribution across robots were implemented, along with blocking schedules (shift changes, narrow aisles).

- Task cancellations, error handling, and manual-control scenarios are supported.

Mobile app for operators

- Work-area operators call robots by scanning a container, track current task status, and view operation history.

- Buffer-zone operators place containers by zones, put containers into and out of circulation, and manage fill-status changes.

- The app eliminates paperwork and spreadsheets and reduces errors.

- All container and task logic is available on the handheld device right on the line and in the buffer zone.

Engineering workstation (web console)

- Manual control of robots and work zones via a web interface.

- Create and edit containers, manage reservations and blocks.

- View telemetry, logs, and errors in a single interface.

- Diagnose and reset robot fault states without stopping the whole system.

Buffer zone for 30+ containers

- A warehouse buffer zone for more than 30 containers and 6 placement positions was built from scratch.

- The workflow algorithm is priority-based rather than FIFO/LIFO, speeding up line servicing.

- The buffer zone optimizes warehouse space usage and reduces robot route intersections.

- Full RMS integration ensures transparency and automation for all container operations.

Result

80% reduction in manual labor

Thanks to end-to-end automation of container rotation.

70% faster container rotation

A significant increase in the speed of servicing production lines.

Line downtime reduced to 5–10 minutes

Previously downtime reached 15–30 minutes.

Over 24 million RUB saved per year

By minimizing errors, reducing staff, and optimizing logistics.

Full digitalization of container-fleet logistics

All operations are transparent, controlled, and automatically orchestrated.

Conclusion

Deploying robotic logistics based on KUKA KMP 1500i and the custom RMS platform transformed Yazaki’s warehouse processes. The system automated container rotation, reduced staff workload, ensured continuous production-line operation, and created a scalable digital infrastructure ready for further growth.

Got an idea? Let's discuss!

Fischer Tech is a consulting-driven IT company. We take on not only development but also responsibility for the growth of your business.