Research: warehouse industrial robots and automation opportunities

A human-friendly breakdown of the types of warehouse robots and how they can help automate logistics.

A quick guide to modern warehouse automation solutions.

Why look at warehouse robots at all

At some point, the phrase “warehouse robotization” started to appear everywhere, but everyone means something different by it: some imagine drones flying between racks, others — smart forklifts.

We decided to put together a simple, human-friendly overview of which robots are already working in warehouses today and what tasks they solve.

It helps you soberly assess where people and pallet jacks are still doing the work in your warehouse — and where it makes sense to hand it over to machines.

Transport robots: AGVs, AMRs, and robotic forklifts

The first big group is transport robots.

AGVs follow fixed routes, almost like on rails: they move pallets, containers, and boxes between warehouse zones and don’t get tired of repetitive trips.

AMRs are smarter robots that plan routes on their own, avoid people and obstacles, and can bring shelves to an operator or escort a picker.

A separate class is robotic forklifts, which take over moving and stacking pallets at height.

All of this significantly reduces the workload on staff and removes hundreds of kilometers of “extra steps” around the warehouse.

AS/RS and Goods-to-Person: how robots help with storage and picking

The second key automation area is storage and picking.

AS/RS systems are highly automated racking structures where a crane or shuttle brings the required tote or pallet to the picking point. This lets you use space very densely while still reaching any SKU quickly.

The Goods-to-Person concept goes even further: the goods come to the operator — either as a rack delivered by a mobile robot, or via conveyors and buffer modules.

People stop running around the warehouse and focus only on order fulfillment.

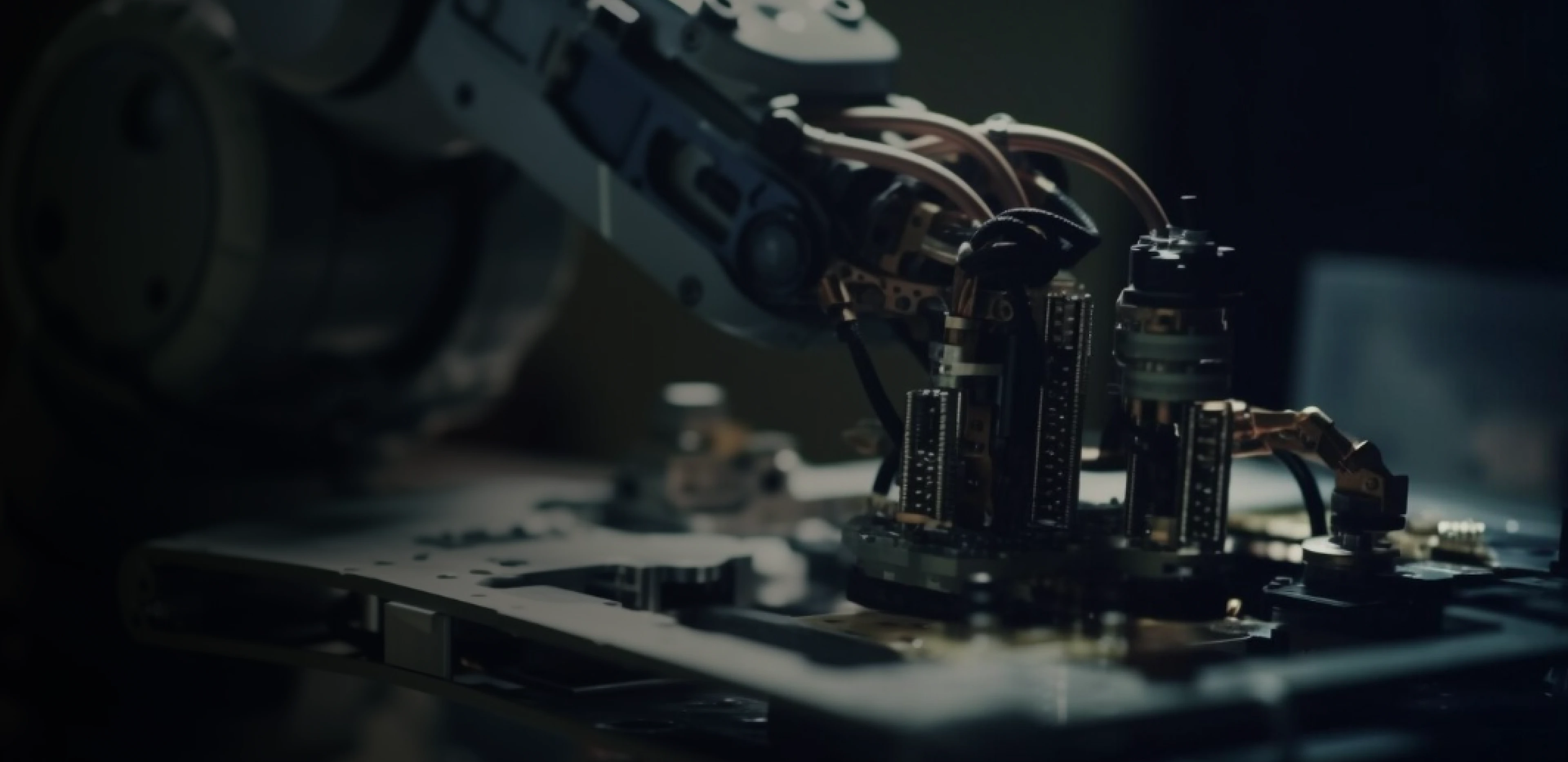

Robot arms: palletizing, order picking, and packing

This is where industrial robot arms come in.

Palletizers automatically stack cartons onto pallets and depalletize inbound pallets, taking heavy and monotonous work off people.

Pick-and-place robots precisely move items from bins or totes into order boxes, guided by cameras and scanners.

Cobots (collaborative robots) can work right next to an operator and assist with packing or sorting without heavy safety fencing.

As a result, “manual labor” turns into process control and tuning, not endless box moving.

Sorting and shipment preparation

A separate pain point for any warehouse is sorting.

Robots help here too: conveyor-based sorting systems with smart diverters, as well as small mobile robots, route parcels by destination, route, or courier.

In parallel, packing machines work: they fold and seal boxes, weigh shipments, print and apply labels.

The outcome is a smooth flow of shipment-ready orders without bottlenecks during peak periods.

Inventory, drones, and warehouse safety

Besides “visible” logistics, there’s background work too: inventory counts, location checks, and safety control.

For this, inventory robots with RFID readers and barcode scanners are used: they patrol the warehouse and reconcile actual stock with the system.

Drones help inspect top rack levels without ladders and the risk of falling.

There are also patrol robots for security and cleaning machines that keep aisles and work areas clean. All of this reduces incidents and makes the warehouse a slightly less extreme place to work.

What warehouse robotization delivers for the business

Putting it all together, warehouse robots deliver three main effects: speed, predictability, and safety.

Operations become more stable, peaks are handled without firefighting, and people spend less time on physically demanding and routine work.

Picking and shipping errors decrease, and warehouse space is used noticeably more efficiently.

We prepared this overview to show what classes of solutions exist at all and to help you choose options that truly fit your warehouse format and your constraints on budget, timelines, and IT infrastructure.

Got an idea? Let's discuss!

Fischer Tech is a consulting-driven IT company. We take on not only development but also responsibility for the growth of your business.