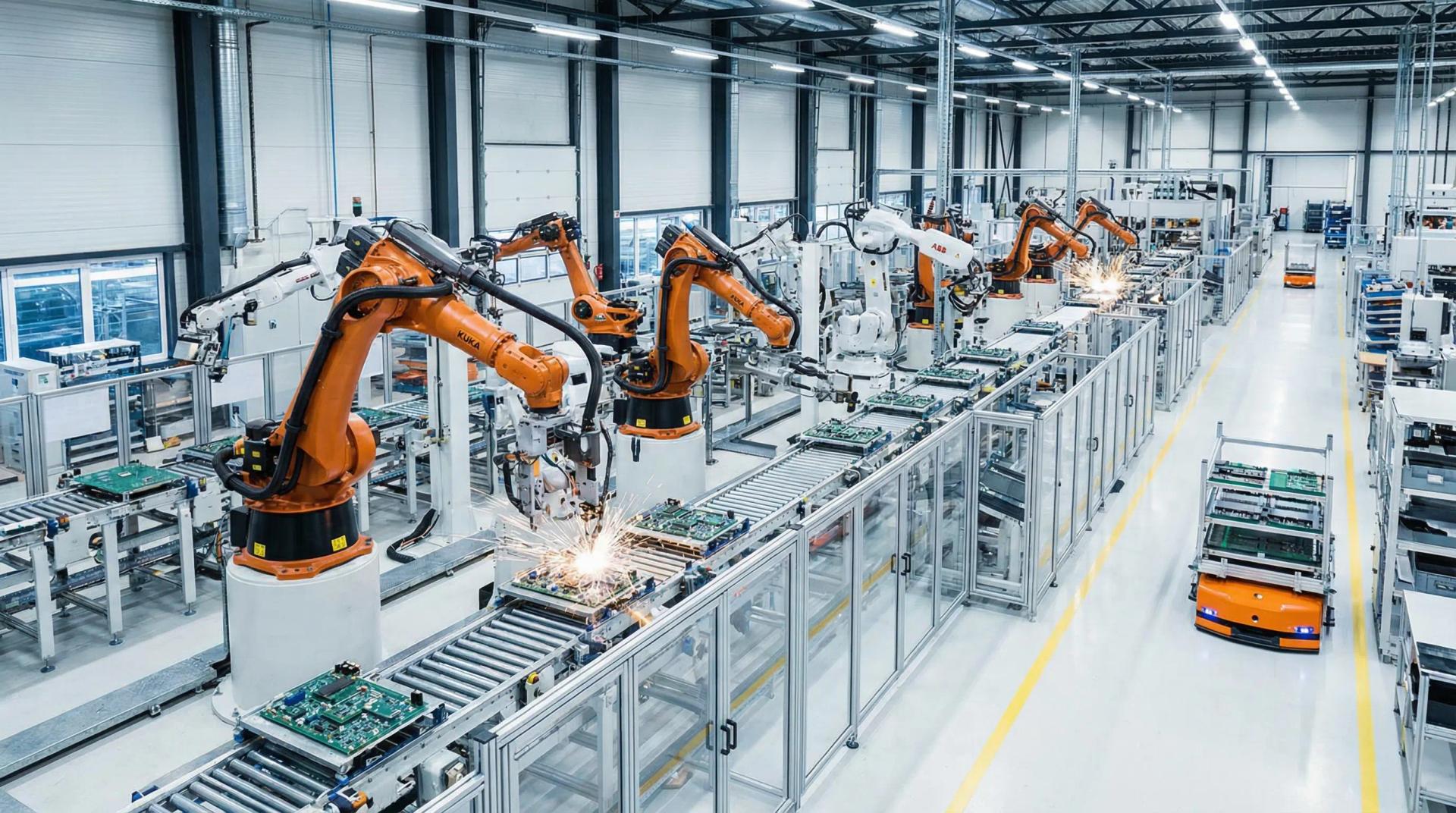

Automation as a response to staff shortages

Why robots and automated systems are becoming a necessity — not a choice — for modern manufacturers.

How automation helps you grow when people are in short supply.

Staff shortages are the new reality for manufacturing

Staff shortages in manufacturing stopped being a temporary issue long ago. It’s not a “tough year” or a “labor-market dip”, but a new reality faced by almost every industry — from machine building and food production to logistics and pharma.

Companies search for people, raise wages, improve conditions — but at some point they hit a ceiling. There is more work, but not more people.

This is exactly where automation stops being a buzzword and becomes a strategic response to talent shortages.

Why staff shortages became a systemic problem

In the past, a lack of people was seen as a temporary imbalance. Today there are too many factors, and they work at the same time:

— demographic decline; — lower interest in physical and shift work; — higher employee expectations for conditions and schedules; — competition between industries for the same specialists; — high turnover in production roles.

It’s important to understand: even if wages rise, productivity does not grow proportionally. People get tired, get sick, burn out, and make mistakes. That’s not “bad management” — it’s the human factor.

Why the “hire more people” strategy no longer works

The most obvious path is to scale headcount. But in practice it fails more and more often.

Key constraints of manual labor:

— dependence on the labor market; — long onboarding and training; — uneven quality of operations; — high injury risk; — rising costs without rising stability.

As a result, production may expand on paper, but becomes harder to manage. Any peak load turns into stress, and losing key employees becomes a serious problem.

What automation delivers under staff shortages

Automation doesn’t solve everything instantly, but it changes the very operating model of manufacturing.

1. Lower dependence on the number of people

Robots and automated lines: — run 24/7; — don’t depend on shifts, vacations, or turnover; — keep a stable operating speed.

This is especially critical for facilities with strict SLAs, serial output, and highly repeatable operations.

Role redistribution, not replacing people

One of the most persistent myths is “robots will replace people”. In reality, something else happens:

— people move away from heavy and monotonous operations; — new roles appear: operators, technicians, and inspectors; — workforce skills grow; — physical strain and injuries decrease.

Automation increases the value of people, not devalues it.

Productivity growth without headcount growth

This is the key effect of automation.

One robot can: — replace several manual operations; — perform them consistently with the same quality; — scale without linear cost growth.

Manufacturing gains the ability to grow not through people, but through systems.

Which automation systems are implemented most often

In manufacturing, companies most often automate:

— transport and internal logistics; — repetitive and heavy operations; — packing, palletizing, and sorting; — automated production lines and cells.

Automation has the highest effect where turnover is the highest.

The long-term economics of automation

Automation often feels expensive at the start.

Short term: — investment; — design; — implementation and training.

Long term: — stable operating costs; — predictable productivity; — fewer losses from the human factor; — lower risk of missed deadlines.

Under staff shortages, the cost of not automating is often higher than the cost of implementation.

Automation as part of an HR strategy

Manufacturers that implement automation get an additional effect:

— employer brand improves; — turnover decreases; — it’s easier to attract younger specialists; — work becomes less physically exhausting.

Modern employees want to work with technology, not be part of an endless manual conveyor.

Conclusion: automation as a strategic choice

Staff shortages are not a temporary crisis — they are a long-term trend.

Manufacturers that rely only on increasing headcount increasingly hit a growth ceiling.

Automation and robotization allow you to: — grow without proportional headcount growth; — stabilize quality and timelines; — make production more resilient to external changes.

Today the question is no longer “should we automate?”, but “where to start and how to do it right”.

Got an idea? Let's discuss!

Fischer Tech is a consulting-driven IT company. We take on not only development but also responsibility for the growth of your business.